One Instant Blog

- Aug 17th, 2023 · A Shooter's Perspective on the ONE INSTANT DIY Camera - by Aidan Avery

- May 25th, 2023 · CHOCO GOLDEN TICKET + YUJI WATANABE / PIBE MAGAZINE

- Feb 24th, 2023 · Introducing ONE INSTANT CHOCO Film - PRE-SALE!

- Oct 13th, 2022 · THE [RE]LAUNCH OF ONE INSTANT COLOR P7 PACKFILM

- Aug 23rd, 2021 · ONE INSTANT PRO TIP #2.2 - PEELING

- Aug 5th, 2021 · ONE INSTANT PRO TIP #2.1 - PULLING

- Jul 29th, 2021 · ONE INSTANT BLACK & WHITE

- Jul 29th, 2021 · GOOD THINGS COME TO THOSE WHO WAIT

- Jul 8th, 2021 · ONE INSTANT PRO TIP #1 - PRINT WASHING

- Apr 30th, 2021 · UPDATE

- Feb 17th, 2021 · B&W PROGRESS UPDATE - SLOW, BUT STEADY...

- Dec 24th, 2020 · TIDINGS OF GREAT JOY - SUCCESSFUL RESULTS FROM 20X24 STUDIO

- Dec 22nd, 2020 · FIRST REACTOR RUN OF B&W REAGENT PLANNED

- Dec 15th, 2020 · B&W FAQ - Frequently Asked Questions

- Dec 11th, 2020 · The Adventure Begins.... ONE INSTANT B&W Film

- Oct 28th, 2020 · Pre-Orders are Caught Up!

- Sep 25th, 2020 · Celebration & ONE INSTANT Merch

- Sep 9th, 2020 · It's a blog! It's an update! It's... NEWS!

A Shooter's Perspective on the ONE INSTANT DIY Camera - by Aidan Avery

Thu 17th Aug, 2023

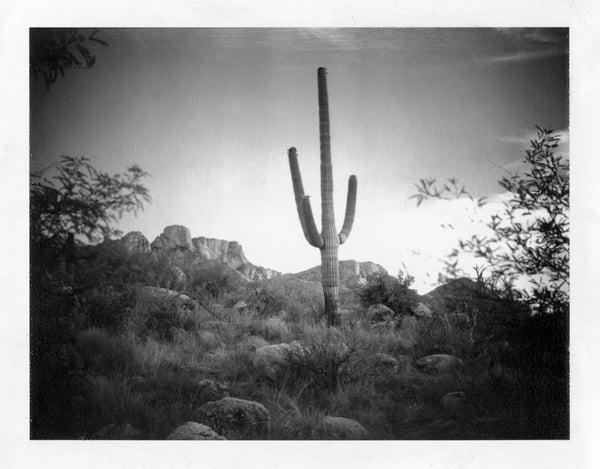

Polaroid 665 Negative (Exp. '09)

50mm Pinhole Camera (10-Second Exposure)

Dear All,

Chris here from ONE INSTANT! In this post, we are excited to share our blogosphere with a guest contributor, specifically our friend, and excellent writer/photographer, Aidan Avery from Tuscon, AZ.

He was gracious enough to do an in-depth review and write-up of our ONE INSTANT DIY camera kit. Not only does he show what amazing photography is possible with our funky little camera, but he does a good job of demystifying the assembly procedure and even shows you how you can shoot packfilms other than ONE INSTANT without losing any functionality! Without further ado, let's let Aidan take the helm...

* * * *

A SHOOTER'S PERSPECTIVE ON THE ONE INSTANT DIY CAMERA - BY AIDAN AVERY

Over the last month, I’ve reveled in the hands-on, do-it-yourself goodness of SUPERSENSE’s ONE INSTANT DIY camera — a limited-edition offering that arrives ready to be built into a powerhouse peel-apart film camera.

The ONE INSTANT DIY kit actually comprises four cameras: three pinhole cameras of varying focal lengths and a sliding box view-camera with a lens. Philosophically, the package is an apt companion to SUPERSENSE’s peel-apart film in that it too brings a hand-made approach to peel-apart photography. (In this case, the hands that make the camera are the photographer’s own). Like ONE INSTANT film, the DIY camera recalls a historical design and repurposes legacy materials—namely, a Fujifilm PA-1 packfilm back and, for the sliding box camera, a 108mm f/4.5 Polaroid Copal lens.

Over the last month I’ve discovered that, also like its namesake film, the ONE INSTANT DIY camera is a unique piece of photographic technology that rewards a thoughtful, intentional approach with high-caliber peel-apart imagery.

ONE INSTANT P7 Color Film

ONE INSTANT DIY Sliding Box Camera (f/9.5, 1/15)

THE BUILD

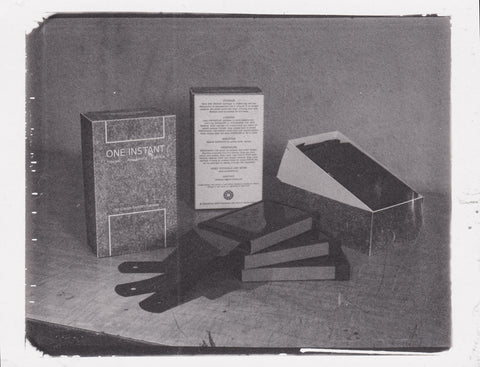

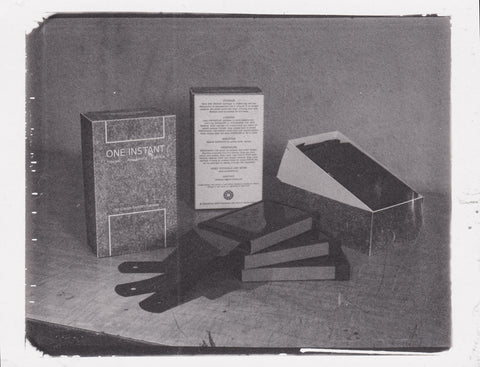

When the kit arrived from Vienna, I splayed out the parts on a table and cleared a work area on the floor below. I had looked over the ONE INSTANT DIY camera microsite and store page. Still, the materials’ high quality impressed me. In hand, the birch pieces that would form the cameras were sturdy and cleanly cut. The lens and film holder — both new-old-stock — were immaculate. And SUPERSENSE had artfully shaped the focusing screen to slip into, and magnetically grip, the back of the PA-1 film holder.

From the box, I also unearthed all sorts of smaller material treasures: a cube of beeswax to lubricate the sliding box camera, a quarter-sized cylinder containing black Indian ink to stain the wood, a canister of putty to fill any gaps, two grades of sandpaper, a sanding block, and more.

Nobody would mistake me for being “handy” when it comes to construction, but building the DIY camera(s) was enjoyably messy and even intuitive. I dabbed glue. I hammered birch pieces together. I puttied. I swabbed ink onto wood. I sanded, inspected, and then inked some more. Finally, I screwed the Polaroid lens into place. Having lost my latex gloves, with ink-stained hands and fingertips coated in glue I laid my work out to dry — proof that building the camera didn’t require construction know-how.

In the well-illustrated instructions, I especially appreciated the steps that left minor functional and aesthetic decisions up to the builder-photographer. Exactly how much would I sand the connecting parts of the sliding box camera? (Until they’re ultra-smooth, I decided.) How much beeswax would I use to lubricate their slide? (All of it, I declared.)

By the time I’d finished, I’d depleted nearly everything in the box — every drop of ink wood stain, all four sheets of sandpaper, and the entire jar of glue. SUPERSENSE had allotted the perfect amount of each. And, since none of the materials are toxic (not even the glue), the camera exemplifies the careful and efficient use of materials I’ve come to expect from SUPERSENSE. Very little waste, and environmentally-friendly components.

THE SLIDING BOX CAMERA

A limited-edition, build-it-yourself camera is a niche product, no doubt. Nonetheless, I’d been anticipating adding the box camera to my arsenal since its 2022 release. Like for many others, discontinued peel-apart film and reinvented ONE INSTANT peel-apart film have played a growing role in my artistic practice. And upon release, the DIY camera filled an important gap in peel-apart image making: it is the only peel-apart camera to offer through-the-lens composition, full film coverage, and precise frame-edge indication.

With a focusing screen that sits in the PA-1 film back, the camera’s projected image is exactly what the film will record. In fact, using the box camera was the first time I’d ever felt total assurance while composing for Type 100-sized peel-apart film. For me, this alone makes the camera a serious piece of instant film machinery. (Not to mention, I found a special joy in seeing the image projected from the lens onto the focusing screen, then imagining how what I saw on the screen would translate onto my peel-apart film.)

Polaroid 665 Positive (Exp. ’09)

Sliding Box Camera (f/4.5, 1/30, Yellow Filter)

I rolled into Catalina State Park in Arizona amidst swarming wasps and a 109° Fahrenheit (43° C) heatwave. Neither of those, it turned out, would dampen an incredibly satisfying first experience with the DIY camera.

Set up at a saguaro cactus near the Catalina mountains, I discovered that the camera’s small size, with little internal light falloff, produces a stunningly bright image on the focusing screen. Focusing the camera is akin to focusing a 4x5 camera. It involves sliding the front standard (or, in this case, front part of the box) forward or backward until the subject is sharp, then locking the box into place. Without precision gears, this initially requires a bit of patience, but the beeswax lubricant is slick and gets slicker with each use. After just a few trial runs I was able to focus the box camera as fast as I would a large format view camera.

The vintage Polaroid triplet lens immediately charmed me. At 108mm, the lens falls into the same general focal length category as packfilm Land Cameras. It’s wide enough for landscape, but tight enough for portraiture. Wide open (at f/4.5), like in the shot of the saguaro cactus, the Polaroid lens displays all sorts of personality, including vignetting, edge softness, and a very shallow depth of field. Stopped down, like in the opening ONE INSTANT shot of Christy, all vignetting is gone and the image is sharp from corner to corner. (Even at its widest, though, the lens is incredibly sharp for a peel-apart film camera. See, for example, the comparison of the Polaroid Type 665 positive and negative of the cactus shot here.)

After just one trek into the desert and one portrait shoot, I was already enamored with the slower, methodical process of shooting peel-apart film with the sliding box camera, as well as with images it produced.

Polaroid 665 Positive (Exp. '09)

ONE INSTANT DIY Sliding Box Camera (f/6.7, 1/15)

THE PINHOLE CAMERAS

If the sliding box camera is the DIY package’s high-end artistic instrument, the pinhole cameras are wonderfully experimental counterparts. They afford long exposures, wide fields of view, and the magic of pure, unobstructed light and time impressing themselves onto film.

Shooting with the pinhole cameras involves the PA-1 back and a magnetic, removable cap that sits over the pinhole and works interchangeably between the three cameras. Snapped into place, the cap rotates open to expose the film and swivels back to conclude exposure. Opening and closing the cap smoothly requires a certain “touch,” similar to focusing the sliding box camera, which is easily learned with a little practice.

Fujifilm FP-100c (Exp. ’12)

50mm Pinhole Camera (20-Second Exposure)

The three laser-cut pinholes each deliver impressive clarity, while the cameras offer varying degrees of wideness in perspective: standard wide angle (50mm), ultra wide angle (35mm), or eye-popping and perspective-bending wide angle (20mm). Without the luxury of a lens and focusing screen, composing with any of the pinhole cameras is necessarily an experiment unto itself. But such is the joy of pinhole photography.

A quick tip for composition: Reverse-trace from the film’s edges out the pinhole to imagine the camera’s field of view (without forgetting, of course, that precision and pinhole-ism are practically antithetical).

Polaroid 665 Negative (Exp. ’09)

35mm Pinhole Camera (1-Minute Exposure)

Between the distinct qualities of pinhole photography (soft visuals, natural vignetting, movement captured over long periods of time) and the equally distinguishable qualities of peel-apart film (saturated colors, endearingly unpredictable results, and other artifacts of expiration), the creative possibilities of the DIY pinhole cameras are inexhaustible. So far, I’ve had the most success with the 35mm and 50mm. My current pursuit is capitalizing on the 20mm’s fish-eye-like perspective, which holds the potential for mind-bending imagery.

FINAL TIP: SHOOTING PACKFILM IN THE DIY CAMERA

The ONE INSTANT DIY camera is made specifically for ONE INSTANT, single-shot cartridges. For me, though, its long-term viability hinged on whether or not I could also use it with the packfilm stashed in my minifridge. Without a darkslide in the modified PA-1 back, switching between cameras or using the focusing screen in the middle of a pack posed a challenge. However, I came up with three situation-dependent solutions to shoot packfilm seamlessly in the DIY camera. The only additional requirement is a film changing bag.

-

To shoot packfilm with one of the pinhole cameras, just load the pack and let it rip. No need for the changing bag.

-

To switch between pinhole cameras, or from the sliding box camera to a pinhole camera, in the middle of a pack, bring the current setup and the desired pinhole camera into the changing back. In the bag, put the new pinhole camera on PA-1 back. (Don’t forget to swap the pinhole cap over as well.)

-

To use the sliding box camera’s view screen in the middle of a pack, save the packfilm darkslide after pulling it for the first shot. When it’s time to refocus or recompose, bring the box camera into the changing bag and remove the film from the PA-1 back. Then, unclip the back of the packfilm’s shell and remove the film. Gently wrap the darkslide around the film, put the film back into its case, and re-clip the back in place. Now the changing bag can be opened safely, the focusing screen put back into the camera, and the packfilm used anew after composition.

Opening the packfilm case may be unfamiliar, but with practice it’s quick, simple, and hard to mess up. The extra 10-15 seconds it takes were well worth the ability to render images on my old packfilm using the sliding box camera and lens.

* * * *

Finally, thank you to Chris Holmquist, SUPERSENSE’s mastermind behind the DIY camera (and ONE INSTANT). Last year I tried to design a rudimentary pinhole box camera myself, and the result was clunky and impractical. The more time I spend with the ONE INSTANT DIY camera, however, the more deeply I appreciate Chris’s artful engineering. I’ll be happy to make this inventive, through-the-lens camera my primary peel-apart shooter for years to come.

—Aidan

* * * *

Thank you Aidan!

For more images from the ONE INSTANT DIY camera, or to ask Aidan any questions about his experience using it (he’s happy to answer!), find him on Instagram or his website.

We can't thank him enough for lending his talents and sharing his experiences with our DIY CAMERA kit.

Best wishes from all of us at ONE INSTANT / SUPERSENSE,

- Chris

If you're interested in purchasing a ONE INSTANT DIY CAMERA KIT... click the photo below!

CHOCO GOLDEN TICKET + YUJI WATANABE / PIBE MAGAZINE

Thu 25th May, 2023

GOLDEN TICKET + YUJI WATANABE / PIBE MAGAZINE

Dear Peel-Apart Saviors,

We are writing this month in order to share two exciting morsels of ONE INSTANT related goodness with you.

First off, we have encouraging and exciting news regarding our new CHOCO film pre-sale, which was announced last time we wrote.

Also, we just had to sing the praises and share the amazing work of one of our favorite ONE INSTANT photographers, Yuji Watanabe, who has done some very cool things with our funky little film lately.

Please read on for all the mouth-watering details...

CHOCO GOLDEN TICKET

"A little nonsense now and then is relished by the wisest men."

In the intervening weeks though, we would LOVE to sell off the rest of our pre-sale quantity, which currently sits at just under 100 remaining packs. In hopes of whetting your packfilm appetite one more time, we are excited to announce a very special promotion - the CHOCO GOLDEN TICKET.

Five beautifully printed letterpress GOLDEN TICKETS will be randomly hidden amongst the outgoing shipments. This means that everyone who has already pre-ordered, and anyone who orders now, will automatically have a chance to become one of the five luckiest peel-apart shooters in the land.

This prize will not come with any of the baggage typically associated with golden ticket winners seen in past chocolate promotions, namely drowning in a chocolate river, or turning into a blueberry, nor does it come with the crippling responsibility of actually having to manage and run the production of such a hand-made product in 2023... (that job is currently taken)...

What it does mean is that the winners will receive TWO extra packs of CHOCO film in their shipments.

And if that wasn't enough, it includes an open invitation to visit us at the CHOCO factory in Vienna (transportation & lodging not included, sadly).

So don't miss your chance to win! We'd love to send off this CHOCO pre-sale in style and make sure that only the most faithful packfilm saviors in the world are rewarded for their support.

YUJI WATANABE + PIBE MAGAZINE

Yuji Watanabe is a photographer based in Paris & Tokyo, who creates wonderfully dreamy and highly evocative images.

The latest edition of PIBE MAGAZINE's Spring/Summer 2023 issue Humoresque features Yuji's photography, which was exclusively shot on ONE INSTANT P7 color packfilm.

Yuji is obviously a great photographer, but we think he also manages to use the funkiness and adventuresomeness of our unique film to its fullest degree.

Please check out the PIBE issue, as well as Yuji's website and Instagram. All of you keen-eyed ONE INSTANT shooters will surely be able to identify a few excellent examples of ONE INSTANT photographs among his galleries.

Yuji Watanabe's Website

Yuji Watanabe's Instagram

Humoresque - PIBE MAGAZINE Spring / Summer 2023

Lastly, everyone at ONE INSTANT / SUPERSENSE wants to say a huge THANK YOU to Yuji! We greatly appreciate you letting us feature your amazing work in our newsletter.

Although stocks are currently running (very) low, jump over to our shop if you are interested in stocking up on P7 film for the summer!

UNTIL WE MEET AGAIN

Don't forget to follow Yuji on Instagram and definitely keep your eyes peeled for more great ONE INSTANT examples in the future.

Also, a friendly reminder that all CHOCO pre-orders of three 3-packs or more get free shipping.

We'll be in touch again soon, but in the meantime, happy peeling and enjoy spring!

From everyone here at ONE INSTANT / SUPERSENSE,

Chris

p.s. As usual, we'd love to hear from you at techsupport@one-instant.com

Introducing ONE INSTANT CHOCO Film - PRE-SALE!

Fri 24th Feb, 2023

After 3+ years of production, we are proud to introduce our third film type to the ONE INSTANT lineup - CHOCO!

CHOCO is a legendary film with roots going back into 20x24", 8x10", and packfilm history. It's a delicious, chocolatey, brown-toned monochromatic film made using P3 negative in combination with PP400 positive and chemistry. As you can see from the experimental prototype shots here, the shadows tend towards dark cocoa and the highlights towards frothy cappuccino.

It's a cross-processed Wunderkind that, rumor has it, was discovered when Kenny Rogers (yes, that Kenny Rogers) and his photo assistant were shooting Polaroid 8x10" and accidentally paired color negative with B&W positive & pod. The result of this happy accident was a film that delights all the senses. We are thrilled to be bringing it back!

Although we still have a fair bit of R&D to do on this new film, in typical SUPERSENSE fashion, we couldn't resist the urge to offer our first 333x 3-packs of CHOCO on a special pre-sale basis. To entice you further, we are excited to announce FREE SHIPPING on all orders of 3 or more CHOCO 3-packs!

Now, since we can't say for sure how long this process is going to take (and because we are infamously bad at predicting such things...), we are taking the safe approach and saying it could take anywhere from 2 to 4 months to start fulfilling these pre-sale orders. You've been warned... this is only for the die-hards!

After we successfully complete this pre-sale, CHOCO will become a regular part of the ONE INSTANT lineup.

* * PRE-ORDER CHOCO NOW! * *

THE [RE]LAUNCH OF ONE INSTANT COLOR P7 PACKFILM

Thu 13th Oct, 2022

Dear Packfilm & Peel-Apart Faithful,

I'm writing this blog entry in order to share some exciting news...

It's been a long time coming, but we are happy to finally announce that ONE INSTANT Color P7 'Type 100' Packfilm is back in stock!

Our partners at the 20x24 Studio have concocted one of the best-looking batches of P7 chemistry that we've ever seen. Thanks to clever re-engineering and their continued R&D efforts, this reagent is truly a thing of beauty.

And that's just the tip of the iceberg - we have more good news to share...

For the first phase of this relaunch, all ONE INSTANT products will be shipped via Austrian Post, resulting in significant savings on a typical film order. This is especially true with shipments to North America, where in many cases the cost will be nearly cut in half!

There has always been a modest 3% discount with our "18-pack" option, but now we've simplified it to make all orders of 6 or more 3-packs discounted by 3%. This will even include mixtures of color and B&W film (as soon as we have monochrome back in stock - more on that below).

On top of that, we're introducing a new discount for the truly dedicated packfilm shooter... buy 10 packs and get 1 free! Or to put it another way, put 11 packs in your shopping cart and you only pay for 10. (This awkward terminology comes courtesy of our finicky ecommerce platform)

We are informally calling this latest discount the "group buy special", since it's the perfect opportunity for organizing a group buy with your fellow packfilm comrades, saving big on shipping, and enjoying the lowest possible ONE INSTANT price.

Since we are expecting a lot of orders, please allow a few weeks of lead time for shipping. Naturally, you will be notified as soon as your package is on its way.

Lastly, you may have noticed the omission of black & white film from today's announcement, but we are hoping to have black & white film available as soon as possible. Unfortunately, it's going to take a bit more time. Of course we will update you as soon as it's back.

From everyone at ONE INSTANT / SUPERSENSE, thanks and happy peeling!

Chris

p.s. As usual, we'd love to hear from you at techsupport@one-instant.com

* * * ORDER HERE * * *

2 COMMENTS

Wed 4th Jan, 2023

Hi Marco,

We sell ONE INSTANT film in 3-packs for €49. One 3-pack contains 3 cartridges, and each cartridge produces 1 picture. A 3-pack produces 3 photographs.

Thanks!

Wed 4th Jan, 2023

good evening I wanted to know each pack how many photos are! Thanks Marco

ONE INSTANT PRO TIP #2.2 - PEELING

Mon 23rd Aug, 2021

PRO TIP # 2.2 - PEELING

Welcome to part 2 of our ONE INSTANT pro-tip about pulling & peeling; two oft-overlooked procedures, but which are very important to the final quality of your print.

At this stage you've already pulled the film insert out of your camera and processing is taking place. You've got about 3 minutes to psych yourself up for peeling while you wait. [p.s. Now is a great time to clean your rollers!]

There's a couple different things to peel. For one, we must peel the positive and negative apart, and then we need to peel off the rails and the masking parts to finish it off.

Peeling Apart

One of the most important things to know is that you should NOT peel ONE INSTANT films like you would peel Fuji/Polaroid, that is, from the back side, on the same end as the pulling tab. The instructions given here by Fuji will most certainly lead to disaster with our film.

The adhesives used for the rails and masks of Fuji/Polaroid were sophisticated heat-activated glues with very low tack, which came off super clean. ONE INSTANT, being the scrappy, ragtag product that it is, relies on off-the-shelf tapes, and that means our rails and masking parts are significantly stickier. So it's best to first peel apart, and then afterwards take care of the rails and mask.

The best way to peel apart a ONE INSTANT is to lay it down on some surface with the backside of the negative facing up, and to grab the trailing corner of the negative while holding down the positive with your other hand. Then slowly peel the negative back and away, not by lifting your hand in the air, but instead by keeping it as low and close to the table as possible and peeling across the print. This is a little tricky to explain, but if you peel low like this, the negative comes off at the sharpest possible angle from the print, which significantly reduces the risk of some goo falling falling back on the print surface.

At this point do yourself a favor and just tear off the positive assembly from the rest of the processing insert.

Now seems like a good time to mention that if (when) you get goo on your hands, don't panic, but be sure to wash them well when you're finished. The goo is highly alkaline and doesn't play nicely with skin after prolonged periods of time. Gloves are a good option for those wishing to be extra cautious. Whatever you do, do NOT get it in your eyes! If you do, flush them immediately with cool water for at least 15 minutes.

Removing Rails and Mask

Moving on... it's now time to take off the white rails and black masking elements. Again, the name of the game is to remove the sticky bits by peeling them off at a low angle, not by pulling them up. This low angle of peeling creates a sharp angle of removal, which is the safest way to remove adhesive tape from a photographic surface.

For the black masking parts, use the same principle; low and slow! If you do it right, you will not damage your print and you'll be left with a beautiful, clean image.

Something we've recently noticed is that our [upcoming] black & white product has a tendency to delaminate more than the color P7. So it's extra important to take care when peeling things off, especially the black masking parts.

That's all for now! As usual, drop us a line at techsupport@one-instant.com with questions or comments.

Liebe Grüße aus Wien!

1 COMMENT

Mon 17th Jan, 2022

Hello from Australia,

Its been about 10 years since I was shooting film and yesterday I got out my polaroid cameras and shot a box of Fujifilm at the local cafe. I gave all the photos away and people were very interested in what I was doing. I have quite a lot of fuji film and impossible Project films in stock. But I thought I would see what’s available to do more and came upon your latest whereabouts here at One Instant.

Now I have an idea for you. You may have tried it. But in case you have not… Regarding the film masking tape around the sides, that sticks and can pull off or tear. Today I happened to go to a sewing shop and I bought some spray adhesive (unrelated to any photography projects) “for gluing textile fabric, paper, cardboard, foil, urethane and rubber foams…” It’s acid free, dries clear and non-yellowing. But the interesting part is, “for a permanent bond, coat both surfaces. For a temporary bond coat one surface only.”

If you are using a masking tape or bought tape, maybe using a spray adhesive like this would be better so it will peel off easily? It’s mainly for fabric gluing so it is flexible and would likely go through the rollers ok. It might mean you can use thinner tape too?

Good luck with all your projects. It’s great that you are making things happen.

I used to do a lot of bromoil printing. I am now an accordion repairer and tuner. So I am still thinking and solving technical problems in a traditional industry. Later on I hope to go back to bromoil printing.

A bromoil print turns a photo into an oil print, so its permanence is like an oil painting. I made bromoils from polaroids and digital negatives, pinhole cameras, everything. Maybe one day there will be an instant bromoil paper image that the photographer can ink up with a brush straight out of the camera! Hmmm, cool idea :-)

best of health to you all.

Tony Peri

Sydney Australia

ONE INSTANT PRO TIP #2.1 - PULLING

Thu 5th Aug, 2021

Our 2nd installment of ONE INSTANT Pro Tips is going to be a two-part series, diving into topics that at first glance seem almost too trivial to be worthy of discussion, but as with many things in life... the devil is in the details!

We're talking about pulling (2.1) and peeling (2.2). That is, pulling the film through the rollers to begin processing, and peeling the negative & positive apart, as well as peeling off all the sticky bits afterwards. Both steps sound simple, but a little extra knowledge will really increase your odds of getting a perfect print in the end.

PRO TIP #2.1 - PULLING

After you've loaded your film and taken a picture, it's time to process it, and this is done by pulling the 'photographic insert' through the rollers, which breaks open the pod and spreads the goo between negative and positive, beginning the ~3 minute processing phase.

There are two important factors to consider here; pulling speed and pulling angle & orientation.

Pulling Speed

From slow, thoughtful pulls of surgical precision, to fast, YOLO rips out of the camera, everyone seems to have their own style when it comes to processing.

An interesting rule of thumb that we learned from the 20x24 Studio is that a fast pull yields a tighter gap, and a slow pull yields a fatter gap.

So what does that mean? Well by 'gap' we're referring to the distance between the negative and positive and the resulting thickness of the goo coating between them during processing. In packfilm, this is overwhelmingly determined by the thickness of the 'rails', but changes in pulling speed do still have an influence.

In theory this rule would imply that a faster pull/tigther gap increases the odds that the whole print surface is coated with goo, producing better coverage (a thinner coating means more goo can spread farther). It also should reduce the chance of 'goo stick', which is the nasty phenomenon of too much ugly yellow goo sticking to the print surface after peeling (caused by a too fat gap).

All of that being said, in actual practice we've not seen a huge effect from pulling speed changes. It's generally on us to choose the right rail thickness to begin with, but since our product can be finicky and a bit experimental at times, I figure it doesn't hurt to share as much information as possible; maybe you can use it to your advantage somehow.

In summary, it's probably best to just find a speed that feels comfortable and in control.

Pulling Angle & Orientation

Now... way more important than pulling speed is the angle & orientation at which you pull your ONE INSTANT. This makes a big difference.

Pulling even a little bit off-axis or off-center can result in several bad things happening; crumpled & misaligned print components, ripped-off positive sheets, uneven & incomplete coverage, and general photographic carnage.

Polaroid knew this well, and thanks to those brilliant product engineers of yore, we can glean some very interesting clues about the right way to pull our Polaroi... errrrr ... ONE INSTANTs.

Many of the consumer oriented Land cameras from the late 60's/early 70's had this rather unique-looking 'T-handle', and in the instructions came the following notice...

PLEASE USE THIS HANDLE to hold the camera when pulling tabs to develop your pictures. DO NOT hold onto the camera body when pulling tabs; if you do, you may spoil your pictures.

The first time I read this I was intrigued, but also puzzled. After a bit of a think though, it became clear which problem they were trying to solve with this funny looking handle.

The goal of a good pull is for the chemical pod to go through the rollers perfectly parallel with them, so that it bursts evenly across the opening, spilling goo across the whole length of the pod and not favoring one side or the other. To achieve this, the axis of pull should be perfectly perpendicular to the rollers and pod.

The biggest obstacle to this, you ask? Your own unwitting death grip on the camera.

So the T-handle decouples your hand from the camera body, which ensures that when you pull on the processing tab, the photographic insert and the camera automatically align themselves along the axis of pull. It eliminates the influence that your grip can have on the alignment of the camera, and thus greatly increases the likelihood that the pod will meet parallel with the rollers.

The Polaroid product designers understood this phenomenon well, and the T-handle was their very clever solution to help the consumer do everything right automatically.

Now the obvious problem is that most people aren't using cameras with T-handles! Well fear not... we can still apply these insights to optimize our pulling technique.

Basically your goal should be to maintain a loose grip, centered opposite from the roller side, ideally in an orientation that allows you to judge to some degree whether or not everything is aligned nicely (i.e. flat on a table or the ground).

What is not recommended is gripping the camera too tightly, or pulling the film insert out when the camera is still around your neck.

With a bit of experience and attention you can even start to feel the moment when the pod hits the rollers, because it will act like a little speed bump. This is the point where if you've done everything right, the camera will automatically align itself, keeping the pod and the rollers parallel. Hopefully, that means your print is going to come out with nice coverage and no carnage.

(if you happen to like photographic carnage, we won't judge, and now you know how to increase your odds of getting it!)

That's all for now. Stay tuned for the exciting conclusion in ONE INSTANT Pro Tip #2.2 - Peeling, and as always, we'd love to hear from you! Please feel free to write me at techsupport@one-instant.com with whatever's on your mind (preferably regarding instant photography...)

Ciao for now,

Chris Holmquist

ONE INSTANT Production Manager

3 COMMENTS

Wed 29th Jun, 2022

One more tip when it comes to pulling. As discussed, it’s a good idea to lay the camera flat on a table when processing, but this ALSO significantly helps the goo in the chemical pod to redistribute evenly. Imagine if you were to pull out the film with the camera (and thus the pod) held sideways… all of the goo in the pod would sink to one side and this would definitely lead to bad coverage. This problem was addressed by Polaroid and Fuji by breaking up the pod into smaller chambers. Polaroid even went a few steps further with trapezoidal sections and what not (see US Patent 3833381 from 1974).

Sadly, this is something that we can’t currently implement at ONE INSTANT due to limitations with our pod machine, but we hope to change this in the future…

Tue 10th Aug, 2021

Thanks! Yep, those Polaroid folks were pretty clever!

Tue 10th Aug, 2021

great tip!

never was sure what these handles are actually good for..

ONE INSTANT BLACK & WHITE

Thu 29th Jul, 2021

Dear Packfilm Saviors,

For the last 9 months or so we've had a semi-secret project going on behind the scenes, but now that we've reached an important milestone we figure we can finally shout it from the rooftops...

We are resurrecting black & white peel-apart packfilm!

This journey is chronicled on our IMPOSSIBLE ONE INSTANT microsite, so if you're interested in digging deeper you can read all about the history there.

But long story short, we did it! Or rather... we're doing it...

The project always hinged on the 20x24 Studio's ability to successfuly recreate the reagent, which proved to be no simple feat of chemical re-engineering. After 9 months of attempts, setbacks, reformulations, bouts of bad luck, extreme weather, broken equipment, bad chemicals... you name it.... the boys in Boston have perservered and managed to pull it off.

John Reuter and his team deserve a ton of praise for their hard work in reformulating this reagent from scratch. They took Doc's impossible vision of resurrecting black & white packfilm and made it a reality. Thank you guys! We think the results speak for themselves...

These test shots from the 20x24" format show the lovely quality of this reagent in combination with the PP400 negative/positive materials. Needless to say, we can't wait to load it into thousands of ONE INSTANT cartridges and ship them all over the world.

Of course our first priority is to fulfill the 3333 pre-order shots that we've promised to the black & white believers, but our big hope is that this marks the (permanent) return of monochrome packfilm.

There are still challenges to overcome, that's for sure. For starters, the stock of b&w film that we have is quite small compared to the enormous stockpile of P7 we've been sitting on for the last couple years. Until we can get an accurate count of the viable film that we have, it's hard to say how much b&w film we'll ultimately be able to produce.

However, the long-term goal is to get our hands on new negative/positive materials, and once we achieve that we are no longer tied to existing stocks of legacy materials, which would be huge.

Our friends over at New55 have proven that this is possible, but the problem with packfilm is that the negative material must be coated on a light-proof film base. This is in contrast to Type55 films, which are processed in a light-tight envelope and thus don't have this requirement.

Suffice it to say, there are many more challenges that lay ahead, but I guess for the time being we should just bask in the glow of the 20x24 crew's achievements, and celebrate the fact that for the time being, there is black & white packfilm once again being made on planet Earth.

In the coming weeks and months we will clarify and announce our plans for the future availability of ONE INSTANT BLACK & WHITE, in addition to discussing the many other exciting projects and products we're dreaming about. So please, stay tuned to this blog!

As usual, we'd love to hear from you at techsupport@one-instant.com and you don't even need a good excuse to write; we just like chatting about ONE INSTANT and packfilm!

Till next time,

Chris H.

Production Manager

2 COMMENTS

Thu 29th Jul, 2021

Great news! I’m looking forward to trying out this film! Thanks for all your hard work.

Thu 29th Jul, 2021

This is incredible news! Despite supporting the project and using film, I was always a little downbeat about the the reagent was going to run dry in time.

I know we arn’t quite there – but I always saw this part as the biggest hurdle. Perhaps that’s just me lacking knowledge, but I am sure with time (and money!) the negative can be resolved.

GOOD THINGS COME TO THOSE WHO WAIT

Thu 29th Jul, 2021

Dear B&W Packfilm Believers,

We have very good news to share with you! After nearly a year of waiting, your patience is about to be rewarded.

A few weeks back, we received an ecstatic email from John at the 20x24 Studio with a simple subject line... HOLY F***ING S***. (pardon our french...)

We knew right away that there must be some good news inside, and indeed there was!

At last, the boys in Boston had succeeded in formulating a truly remarkable black & white reagent!

The results speak for themselves; gorgeous blacks, good contrast, no mottling or streaking, high sharpness.... wow, wow, WOW!

We are extremely grateful for the hardwork that John and his crew put in over the past year. There were a lot of ups and downs, but they have every reason to be extremely proud of their efforts.

The whole ONE INSTANT / SUPERSENSE sends a huge THANK YOU to John and his team!

Within a week of this great news, we already had in our hands an express shipment of test pods, and we got right to work dialing in the right rail height, testing our different film stocks, and understanding the full capabilities of this film and reagent.

After just a few shots, we were in love with the results in ONE INSTANT format...

So, what are the next steps you ask??

Well, we are now waiting for the big shipment of 3333 pods to fulfill all the pre-orders, and we are expecting to be able to start production in late-August/early-September. If all goes as planned, we think we can finish up all these orders before the first autumn leaf hits the ground. It should be doable!

In the meantime, sit tight, start polishing your lenses, clean your rollers, calibrate your light-meters, and get ready to go shooting with ONE INSTANT BLACK & WHITE.

As usual, please write to techsupport@one-instant.com with any questions, concerns, queries, compliments, ideas, etc.

Warm wishes from Vienna,

Chris H.

ONE INSTANT Production Manager

2 COMMENTS

Fri 30th Jul, 2021

Wowwww What brilliant news 😊

Can’t wait for this to come through my letterbox (once I’ve ordered it)

Well done all 😊

Iain H C

Fri 30th Jul, 2021

Glad to see the 672 negative that I designed(had the idea to use the gray base and assisted in implementing it)finally working well again. Glad to have assisted Gerry, Ted and John with goo changes. wishing you much success.

ONE INSTANT PRO TIP #1 - PRINT WASHING

Thu 8th Jul, 2021

Dear ONE INSTANT Shooters,

Welcome to the first-ever installment of our new 'Pro Tips' series!

Over the last couple years we've developed several methods of getting improved results with ONE INSTANT film, and instead of keeping them to ourselves we decided it was time to share them with the community. We plan to make this a regular thing, and of course we would also love to hear feedback and/or suggestions from anyone who has a bright idea to share; just fire off an email to us at techsupport@one-instant.com

PRO TIP #1 - PRINT WASHING

Our first pro tip is something we call print washing, and as you'll see, it's about as simple as it sounds.

You may have experienced that the surface of a ONE INSTANT print can sometimes takes on a matte surface charasteric after it has dried. According to the 20x24 Studio, this effect is known as 'salting out' and is caused by the formation of potassium hydroxide crystals originating from the reagent chemistry. It is more pronounced when the coating of reagent (a.k.a. the goo in the pods) is thicker on the print, though it also seems to get better or worse somewhat randomly between different batches of reagent chemistry.

Whatever the true cause of it is, we don't really like it. The good news is, there is a simple way to get rid of it!

PRINT WASHING

1. Turn on a cold water tap and set it to a moderate output level. Avoid high pressure or a too violent flow; this might damage the print surface.

2. Rinse the print thoroughly for around 10 to 15 seconds. Hold the print relatively close to the tap so that it gently and completely floods the surface.

3. Hang the print to dry in a dust free environment, ideally at an angle so that the water runs down to a single corner. Never touch the surface of the print while it's wet.

4. Once dried, the matte effect should be eliminated, or at least greatly improved.You have gone from matte to gloss!

Now, for a few caveats and important pointers...

Once the print has gotten wet, the image layer is extremely fragile. You must be exceedingly careful with how you handle it to avoid ruining your precious instant photograph.

Rinsing the print for more than 20 seconds becomes very risky. ONE INSTANT prints are not like darkroom prints and therefore should not be subjected to water for significant lengths of time. As soon as the print becomes wet, the image layer gets saturated and is in a very delicate state. Treat it kindly.

Once the print is hanging, you might notice that the image layer has swelled in places, exhibiting very strange relief patterns. Don't worry, once it is dry these will disappear.

Lastly, in some of our tests, we came across prints that were not completely fixed by this method. We are left scratching our heads, but have concluded that these examples of matte effect or salting out must be due to some other phenomenon. The mysteries never cease...

We hope you found this helpful, and we hope you try out this very simple method for enhancing the quality of your ONE INSTANT prints!

Experiment, have fun, but just don't end up like this guy...

1 COMMENT

Fri 9th Jul, 2021

Oooo, that’s one way to do an emulsion lift!

UPDATE

Fri 30th Apr, 2021

Dear B&W Believers,

Before we update you with the latest news on our efforts to bring back black & white packfilm, we must first say a big THANK YOU!

We've officially sold out of all 3333 shots from the b&w pre-order, and we can't wait to get them into your hands and cameras across the world!

Everyone who has pre-ordered black & white film should be recommended for sainthood because lately we've had zero emails of irate impatience about the fact that it's all taking longer than we intially planned, and for that we are humbled and very grateful. You packfilm saviors are the best!

Over the last several months there were a number of technical setbacks, and improvements have been frustratingly slow. But we can finally say that the results are really getting somewhere! The latest b&w reagent tests in 20x24" format are looking really good (see above), and the boys in Boston aren't even finished yet.

Some hard-to-source chemicals have finally been procured, and John and his team are currently going through the tedious task of experimenting and tweaking the formula.

Additionally, some new recruits in the form of deeply experienced Polaroid retirees are joining forces with the 20x24 Studio, which is very exciting news for the future of this project.

All in all, by the time the final b&w formula is settled upon, we're expecting a truly gorgeous b&w product!

Now, although we can't pin down a solid date yet, it feels like the home stretch. We're hoping pre-order deliveries can begin shipping before summer hits.

In the meantime, the ONE INSTANT production team has been anything but lazy. They have prepared nearly all of the necessary cartridges, caps, positive assemblies, etc. All that's left is the darkroom work of attaching negatives and pods.

Due to all this prep work, the final steps will go very quickly, and we anticipate ONE INSTANT B&W pre-orders flying out the door as soon as pods arrive.

So that's all for now.

As usual, please feel free to email us at techsupport@one-instant.com with any questions, queries, concerns, or comments!

Hopefully we will have some more good news soon!

On behalf of the whole ONE INSTANT / SUPERSENSE team,

Liebe Grüße aus Wien,

Chris

* * *

B&W PROGRESS UPDATE - SLOW, BUT STEADY...

Wed 17th Feb, 2021

Dear Packfilm Saviors,

Lately you may have noticed some 'radio silence' regarding our black & white packfilm resurrection, and judging by the recent emails we've been getting, you're chomping at the bit to get an update! I'm here to get you up to speed.

As usual, there's some good news and some less-than-good news.

First, let's get the less-than-good news out of the way...

The old Polaroid pod-filling machine (a.k.a. the Pod Runner) at the 20x24 Studio has had to undergo some unforeseen maintenance and this has meant an unfortunate delay of several weeks.

This beast of a contraption hails back to the 1960's, and as you can rightly imagine, it is one of the most important mechanical pieces in the 'saving packfilm' puzzle. When it breaks down, the 20x24 team has to move heaven and Earth to get it back up and running.

To make matters worse, the Boston area has been getting hammered pretty good lately with snow and wintry weather, and this has impacted the guys' ability to get to the shop easily. Add in the concern of COVID safety, and it's taken way longer than normal to get electricians and repairmen in to complete the necessary work. However, rest assured that the ball is rolling and it's just a matter of time till all of that is sorted out.

The good news is that we are nearly sold out of our pre-order supply! Nearly 87% of the promised first-run of black & white film has been sold, which indicates that the appetite for this film is tenacious. The support and enthusiasm we've received from everyone is just great, and we can't thank you enough.

Despite having no pods yet, we are still able to keep busy in the Vienna manufactory; prepping and assembling all that we can, so that as soon as we get pods we'll be able to make quick work of slapping them on and shipping the pre-orders out the door.

So stay tuned, and hopefully we'll be able to share some truly excellent news with you all in the coming weeks.

Till next time,

Chris

ONE INSTANT PRODUCTION MANAGER

TIDINGS OF GREAT JOY - SUCCESSFUL RESULTS FROM 20X24 STUDIO

Thu 24th Dec, 2020

We just received amazing news from John and his team; their reactor run was successful and we have confirmation that a black & white reagent is again possible!

John's words tell it best...

"Hi guys,

Rising at 5:30 on this cold December morning to meet by 9:00 at the lab, I had only slim hope that we could pull this off. But pull it off we did. This spread was done minutes after the reagent was out of the reactor, probably was around 125º(F), which we would never do but since an answer was really needed so as not to spoil our Christmas I ran it anyway.

And yes, this will work. We are still lacking a toner and developer that can take away the warm tone but I like it and think we should run it after the holiday when it cools down and settles a bit. The important thing to me is always the D-max and this has a very good one. The contrast in the scene is adversely impacted by the crazy temperature but I believe it will settle down once we find the best gap setting for this reagent. I am also working with BW negative and positive that is likely to be from the early 2000s...

best,

John"

To John and his team... congratulations! You guys have made our year!

This ensures that 2021 will see a new black & white packfilm resurrected from the dead, and this is certainly cause for celebration.

Also, this means we've officially entered phase 2 (price jumps up to €9/shot).

So enjoy the last days of 2020, and we hope this little bit of good news has added some sparkle to your holidays.

- Chris

FIRST REACTOR RUN OF B&W REAGENT PLANNED

Tue 22nd Dec, 2020

Dear Black & White Believers,

Please cross your fingers and say a little (non-denominational) prayer for our friends at the 20x24 Studio.

A veritable avalanche of pre-orders has enabled us to immediately get the ball rolling on the resurrection of black & white packfilm, and the boys in Boston are already planning their first reactor run of reagent.

If all goes well, we might hear some good news before Christmas, but more likely we won't know how it turned out until 2021.

We know you're excited, but patience!

Now... we're not an overly superstitious bunch, but I'm quite sure that a few hundred good vibes sent in the direction of John and his team wouldn't hurt.

So please, send them express, without delay, and if we've all been good boys and girls in 2020, maybe Santa will surprise us with something extra-special underneath our trees this year...

In the meantime, this might be the last chance to pre-order at the unbelievably low price of €8/shot!

- Chris

B&W FAQ - Frequently Asked Questions

Tue 15th Dec, 2020

Here are answers to some frequently asked questions we've been getting lately. This information is relevant as of December 15th, 2020.

When will production of the new black & white film begin?

We're not sure yet. We're waiting for initial results from John and his crew at the 20x24 Studio. Assuming everything goes smoothly, we hope to start production in February 2021, or as soon as we get our hands on the new pods.

How long will it take to fulfill all the pre-orders?

We can produce about 200 hand-made cartridges ("shots") per week. At that rate, it should take about 4 months to finish the pre-sale of 3333 shots. There is a good chance we can do it quicker, but at this point we'd rather be conservative in our estimate.

When will pre-orders start shipping and when will I get mine??

As soon as we can start production, shipments will begin to go out the door. Unlike our Kickstarter, we are going to follow a very strict first come, first served fulfillment order. Simply put, your order will be fulfilled in the order it was received.

What is this "reagent" anyways?

It goes by many names; reagent, goo, pod chemistry, processing jelly... whatever you call it, it's crucial to any instant image forming system. It's the stuff that goes in the pod and which gets spread between the positive & negative materials by the rollers in your camera. It's specifically engineered to match the positive/negative system, and right now we're not 100% sure if the boys in Boston can make it or not. Drück die Daumen!

What happens if new black & white reagent can't be produced?

God forbid... your pre-order will be converted into ONE INSTANT P7 color film. Sorry, no refunds!

What film speed (ISO) will the new black & white film be?

Interestingly, we don't know yet. It will completely depend on the characteristics of the new reagent and how it performs with different rail thicknesses.

Why do some of the test examples look neutral black & white, while others appear more sepia and warm-toned?

Good question! We are equally baffled by this. Some of our earliest tests were very neutral, with true blacks and whites. Other tests exhibited much warmer tones, with eggplant blacks and 'coffee & cream' highlights. This is probably due to variability in the old (and quickly degrading) pods that we've cut down and re-sealed for tests. The final product should be much more consistent and predictable.

How many b&w films will you be able to produce in total?

We can't say for sure at this moment, but a preliminary look at our inventory suggests that we might be able to make well over 10,000 ONE INSTANT black & white shots. That being said, this pre-order is just for a limited quantity of 3333 shots (1111 3-packs).

What will happen when you run out of the legacy Polaroid materials?

We get this question a lot. Everybody is understandably anxious to secure a long-term and sustainable future for packfilm. However, having access to these legacy Polaroid materials now gives us the best possible opportunity to develop new materials in the future.

It enables us to focus on the complexities of packfilm production without needing to undertake the herculean effort of simultaneously developing an instant positive/negative system from scratch. Although these films will run out someday, they are directly financing our efforts to save packfilm and will one day result in the introduction of newly manufactured instant film & paper materials. This is the ultimate goal of ONE INSTANT.

- Chris

5 COMMENTS

Wed 25th Sep, 2024

I just bought a Polaroid 220 Land Camera at a garage sale for $5. I intend to give it to my photography-expert kind of son who works for Google in Zurich. Can I buy film for this through One Instant to include? Would it be cheaper to have it shipped to Zurich than NYS in US? Thanks! Very intriguing stuff!!

Sat 26th Dec, 2020

Hey Nick,

That’s interesting! Thanks for sharing; I didn’t know that.

Sat 26th Dec, 2020

Thanks for the update! Even original Polaroid pack film sometimes varied in speed. They would just put a sticker or note with the batch of film to turn the lighter/darker knob one way or the other!

Tue 22nd Dec, 2020

Thanks KTA!

Tue 22nd Dec, 2020

‘Rather than don’t exist anymore.’

Even the old Polaroid and doctor land did (kind of) same experiment. Please don’t give up and keep moving foward to archive gole for reviving old peel-a-part wonders beyond the one instant.

Always support’in.

-Korea Telecommunications Authority

The Adventure Begins.... ONE INSTANT B&W Film

Fri 11th Dec, 2020

Dear Saviors of Packfilm,

ONE INSTANT production manager Chris here, writing to you with an exciting bit of (potentially) very good news. To get right to the point... we might be able to offer black and white film in the ONE INSTANT format; our very own version of a revived Polaroid 672 type black & white film.

Before you get too excited though, let me explain the whole situation in a little bit more detail...

Back in 2017, John Reuter and his team at the 20x24 Studio mixed up the last batch of reagent for a black & white material known as PP400. This is the exact same film/paper used in the legendary Polaroid 672 and 664 black & white films; PolaPan materials that were particularly beloved among the countless photographers who shot on them.

This final batch of pods was intended to serve the few remaining master rolls of PP400 material on hand in Boston, as well as the half-dozen or so cases of 20x24" material that SUPERSENSE had down in their cellar in Vienna. Indeed, this was supposed to be the end of the line for b&w in the 20x24" format, due to the fact that one of the crucial chemicals in the formula had run out and was not easily replaceable.

Flash forward to a few weeks ago, when John (during a lockdown inspired house-cleaning) uncovered an additional canister of the missing polymer used in the reagent formula.

The implications of this discovery were immediately evident; it meant another chance to produce fresh pods for a black and white packfilm!

Upon receiving this news from the States, Doc directed me to go down and take stock of our inventory of PP400 materials, which much to our delight was way more than we thought; still sealed and fresh. We also had a handful of the 2017 20x24" pods on hand, and although badly oxidized and in pretty rough shape, they were good enough for a few quick & dirty tests.

So, we have a significant amount of PP400 material on hand in Vienna, but we need fresh pod chemistry if we want to offer a ONE INSTANT b&w film. John and his crew have just discovered that they have the potential to make new pods, but they still need to make the necessary tests to ensure that their chemicals have remained viable. (they are, after all, not exactly fresh)

But a distinct scent of optimism fills the air, and it is only out of an abundance of caution that John is giving it a 50/50 chance of success at this stage.

Now, if you know SUPERSENSE, 50/50 chances are exactly the kind of impossible odds that our founder Doc Kaps thrives on, and Doc has wasted no time in coming up with an ambitious plan to support the R&D efforts of John and his team.

This endeavor requires a fair amount of pre-investment, and with the reality that 2020 has been a particularly hard year for all of us financially, we've decided to launch a pre-sale offer for the first 3333 shots of ONE INSTANT B&W film in order to bankroll it.

We are once again counting on you, the packfilm saviors, to help make this dream come true. Doc and all of us at SUPERSENSE believe 111% in our analog SUPERHEROES in Boston, but we need you to join us to make it real.

We've all hit the ground running here, with Ema and Anna in the print department already stamping out some prototype boxes, and assembling a few cartridge mock-ups to show you what the finished product will look like. We're continuing to make tests with the limited number of old pods that we have on hand, and already starting experiments with different rail thicknesses and so on. Meanwhile, hard at work in the States, John is preparing everything needed to mix up the first test batches of reagent.

So without any further ado, I would like to share with you the rather exciting and adventurous pre-sale format that Doc has come up with...

Phase 1: Begins now.

Pre-order ONE INSTANT B&W Film for a very special "True Believer Deal".

The price starts out at 8 EUR/shot. This price will hold until Phase 2 begins.

Phase 2: Begins when John and team have mixed their first successful batch of fresh PP400 reagent and shared their 20x24" format results with everyone.

Then the price will jump to 9 EUR/shot. This price will hold until Phase 3 begins.

Phase 3: Begins when we've received new pods in Vienna and have shown you all that they work well with our materials in the ONE INSTANT format.

Then the price will jump to 11 EUR/shot; the final price. The pre-sale is for a limited amount of 3333 shots.

Phase 4: Begins with production. The timeline depends on how long the R&D process takes, but we hope/anticipate that production will begin in February 2021. We will start shipping as soon as we can, at a weekly production rate of approximately 200 cartridges, with orders being fulfilled in the order they were received.

Now... a very important point.

Since we are asking you to buy a product that doesn't actually exist yet, we've come up with a safety net that should give everyone complete peace of mind. In the worst-case scenario that the boys in Boston truly cannot achieve a successful run of fresh pods, all b&w pre-sale orders will be converted to ONE INSTANT color cartridges. That essentially means that your only risk is getting ONE INSTANT color shots at the lowest price ever. Should this (sad) circumstance come to pass, we would probably know by February.

So what do you say? Are you in?!

Please let us know what you think about this crazy endeavor by either emailing us at techsupport@one-instant.com, by commenting here on our blog, or by letting us know via Instagram at #oneinstantfilm.

Spread the word, spread the faith, and be sure to check back here regularly for updates on our progress.

Here's to the future of packfilm!

26 COMMENTS

Mon 17th Jan, 2022

When can we expect another batch of Type 100 B&W film? Would really like one for my old Polaroid :)

Fri 30th Jul, 2021

Hi Patrick!

We are fully planning on offering this film in the future. Stay tuned for more info, hopefully soon…

Fri 30th Jul, 2021

Will there be another offering once the first orders are filled? I want some.

Fri 30th Jul, 2021

here, just take my money.

Tue 8th Jun, 2021

Hi Sven,

Yes! Please see the latest blogposts for the latest updates. Although things are unfortunately dragging on a bit longer than we would like, the 20×24 guys are working diligently to get the new formula up to quality standards. That being said, they are not able to work on it full-time, and there have been a number of setbacks that have just slowed it down.

To stay up to date with all updates, please sign up for the ‘SAVE PACKFILM’ Newsletter here —> http://eepurl.com/dJPqg6

Many thanks for everyone’s support and patience.

Chris

ONE INSTANT Production Manager

Tue 8th Jun, 2021

Is this project actually still alive?

Fri 1st Jan, 2021

Some exciting news!

Need this NOW!! ♥️

Sun 13th Dec, 2020

Hi! I hope that not to late to get in into phase 1 of the B&W Kickstarter

Sat 12th Dec, 2020

In. Absolutely, I’m in. When can you take my money? I want ALL of this stuff to come back… next, I want to see an attempt at assembling Type-40 roll film from all these efforts… and I’ll buy that, too..

Sat 12th Dec, 2020

I put my money where my heart is, Ordered some B&W and some additional colour film, but my pioneer code did not work, first it did for the colour film (which I expected) but later in the check-out process it was not possible to be used.. (Also just ship everything at once, I don’t want two separate deliveries to look after, I can wait with a few kickstarter shots left)

Sat 12th Dec, 2020

Just 1 question:

How do I order Phase 1?

Sat 12th Dec, 2020

that’s wonderful news!!! Good luck with all of this! I hope it all takes off.

Sat 12th Dec, 2020

Im here! I missed out on the first kickstarter of colour one instant, I’m definitely here to support B&W.

Sat 12th Dec, 2020

Wow, great news! Even if this is very limited I hope it’s a proof of concept that OneInstant can be made with other types of film and chemistries!

Oh, since this is a public post, I don’t think it will be a secret for long… Will you be selling this to people with the pioneer cards?

Sat 12th Dec, 2020

*664, not 644. Warm tone, high latitude, no print curling. Solid performer. Please bring it back!

Sat 12th Dec, 2020

ich bestelle gleich vorab 18 Schuss

Sat 12th Dec, 2020

Ordered and eagerly awaiting!

Fri 11th Dec, 2020

B/W looks quite cool. It would be very interesting to try.

Fri 11th Dec, 2020

I really would like to try this 672 packfilm :). I would like some ofcourse :)!

Fri 11th Dec, 2020

Please hurry!! I’m ready to purchase!!! Spread the word the more we sell the cheaper it is!!

Fri 11th Dec, 2020

Sweet! ❤️

Fri 11th Dec, 2020

Hey Richard! Of course you can order multiple 3-packs. If that’s not working, let us know, but I think there shouldn’t be a problem with putting multiples into the checkout…?

Fri 11th Dec, 2020

O.M.G! This has made my year 😍.

Fri 11th Dec, 2020

The test shots look great! This is an exciting prospect, but… The cost to ship a single 3-pack to USA exceeds the cost of the 3-pack! Unless it’s possible to order multiple 3-packs, this, regrettably, doesn’t make sense for me.

Fri 11th Dec, 2020

Bought.

Any further detail on what might happen when you’re out of legacy material? I love One Instant but I’m very precious with it due to it’s scarcity – which feels wrong for instant film!

Fri 11th Dec, 2020

Fantastic news, good luck with your development efforts! 😊💕

Pre-Orders are Caught Up!

Wed 28th Oct, 2020

Just a quick bit of good news,

All pre-orders (save for a few USA stragglers which will be fulfilled in the coming 2 weeks) are caught up!

That means ONE INSTANT orders now ship as soon as they are placed.

Chris

Celebration & ONE INSTANT Merch

Fri 25th Sep, 2020

Dear Packfilm Saviors,

It's been a challenging spring and summer for, well... basically everyone on Earth I guess. But in spite of all the doom and gloom, the ONE INSTANT team would like to brighten things up with a bit of good news.

This September we have officially completed our inaugural Kickstarter campaign, which saw over 2000 backers receiving nearly 20,000 ONE INSTANT film cartridges. This represents a giant step towards a long-term future for peel-apart instant film, and although I'll admit we didn't win any awards for speediness, our belief is that slow and steady always wins the race!

The community behind us makes this all possible, and they (you!) cannot be thanked enough. The support, the encouragement, and most importantly the photographs from the last year and a half have been amazing. Thank you all!

As we rush to finish up the final North & South American pre-orders, which will be leaving Europe September 30th, to be distributed by Retrospekt in early October, we'd like to do something to celebrate...

We've teamed up with our friend (and talented ceramicist) Rici @ricisart to screenprint some very special ONE INSTANT t-shirts and bags, with all profits going directly to support our efforts to save packfilm.

There's a number of things that make these bags & shirts so special. For starters, Rici has sourced top quality fair-trade gear, and uses only eco-friendly inks. As you'd expect, every piece will be hand printed in the SUPERSENSE manufactory.

But what we think is one of the coolest things is how we made the design itself. Lemme explain...

Screenprint/Silkscreen 101: A screenprinting screen is produced by coating a fine cloth mesh with a light-sensitive emulsion. This coating hardens when exposed to UV light, rendering it insoluble. When certain parts are protected from the UV light, they remain soluble and can be washed away later. With this simple technique, you can expose a screen to almost any kind of pattern or image, wash away the soluble aprts, and voila, you have created a printing matrix that allows ink to pass through in some places and not in others.

So typically these days, people are using digital intermediates to accomplish this, but we've opted for a decidedly more analog approach...

Using actual ONE INSTANT production parts!

The parts were simply laid out on the screen and we flicked on the exposure lamp. We then had a perfect 1:1 contact print of our parts on the screen, which means, if you wanna get philosophical, that when you get your shirt or bag, it has been in direct contact with a screen that was in direct contact with our production parts here in Vienna. Jeez, it's like you were basically here!

But seriously, we wanted a design that celebrated the step-by-step way that ONE INSTANT is being developed and assembled. We wanted a tangible reminder that our product is truly made ONE INSTANT AT A TIME. We also thought this line was a cool bit of Lebensweisheit.

Now to be honest, we're not sure what to expect with this foray into the world of apparel. We're not exactly a clothing company, and because of that, we've decided to dip our feet in slowly and test the waters a bit.

What that means is, we'll be offering the t-shirts and bags for a limited time only. About 2 weeks. Then, once all the orders are placed, we will order precisely the materials we need, print them all, and get them shipped out within 4 weeks.

Now I know what you're thinking.... is this going to be another long and drawn out pre-order process?! The answer is NO. Scout's promise. Rici is a pro, and we're all set up to rock as soon as the orders are in.

If you're reading this, the t-shirts and bags are already for sale on our website, and the sale will end at 11:59pm on Sunday, October 11th, PDT (that's Pacific Daylight Time, or UTC -7).

If this sale is a success and people actually like our funky shirts and bags, we will definitely keep doing it. We're already dreaming up new designs... and of course we'd love to hear your input! As always, feel free to write to tech-support@one-instant.com for any and all ONE INSTANT related things.

Well, as I am wont to do, I've said enough by now... but get 'em while you can, get 'em while they're hot, get 'em while they're still wet & drying, and tell your friends!

On behalf of the whole ONE INSTANT and SUPERSENSE team,

Instantly Yours,

Chris

ONE INSTANT Production Manager

1 COMMENT

Tue 8th Dec, 2020

Just a quick update; there are currently a few “leftover” shirts & bags available for sale in the online shop.

It's a blog! It's an update! It's... NEWS!

Wed 9th Sep, 2020

Welcome!

This is the new platform for keeping up to date with all things ONE INSTANT.

Upon completion of our Kickstarter project in the summer of 2020, we figured it was right & proper to have a right & proper place to share updates, talk shop, discuss complex nuances, and generally spread the news about our continued efforts to save pack-film and keep it alive in the 21st century.

We hope you bookmark this here page and check back often. We plan to provide regular monthly updates (at least), and hopefully even more frequently than that, assuming we have real exciting stuff to discuss.

Best wishes from all of us at SUPERSENSE and ONE INSTANT,

Chris Holmquist; ONE INSTANT Production Manager

2 COMMENTS

Tue 9th Jan, 2024

Hi Steve! Check out the shop page for B&W ONE INSTANT film here → https://the.supersense.com/collections/packfilm/products/one-instant-packfilm-type-100-pp400-b-w

Our B&W film is ISO 400.

Best,

Chris

Tue 9th Jan, 2024

Ok..I’ve scanned all the previous posts and still haven’t found an answer to this question. Perhaps now shooters can jump in with personal opinions… What is the speed of the B&W packs?? I’m putting mine through a Mamiya RB67 thus needing a meter.. HELP!!

ONE INSTANT

ONE INSTANT